7. Decentralized Cooperative System that Responds Quickly to Changing Circumstances by Mimicking Interactions between Animals Engaged in Collective Behavior

Along with advances in the Internet of Things (IoT), social infrastructure systems such as those for electric power, transportation, and distribution have become increasingly large and complex over recent years. In the case of regional power system infrastructure, for example, which is made up of a large number of power plants and substations, the current practice is to use centralized control systems in which a control center handles the aggregation and calculation of data such as electric power generation capacity and sends out instructions to individual sites about how to transmit and distribute power. However, as operation becomes more complex due to the wider adoption of smart grids (next-generation power transmission networks) and the introduction of electricity market liberalization, the use of centralized control systems for system-wide optimization will impose very large computational loads, potentially making real-time performance impractical.

Hitachi has been looking at the collective behavior of animals as a way of resolving this problem. Each individual in a flock of birds or a shoal of fish, for example, determines its direction and speed through interactions (collision avoidance, alignment, and aggregation) between itself and its neighbors. Through the ongoing repetition of these interactions, animals are able to retain an orderly and regimented formation, with the ability to change direction as a single entity and to exhibit coordinated group behavior. That is, through each individual's interactions with its neighbors, this collective behavior of animals gives a group the appearance of acting like a single entity despite lacking any leader (analogous to the control center in a social infrastructure system) keeping track of the overall situation of the group.

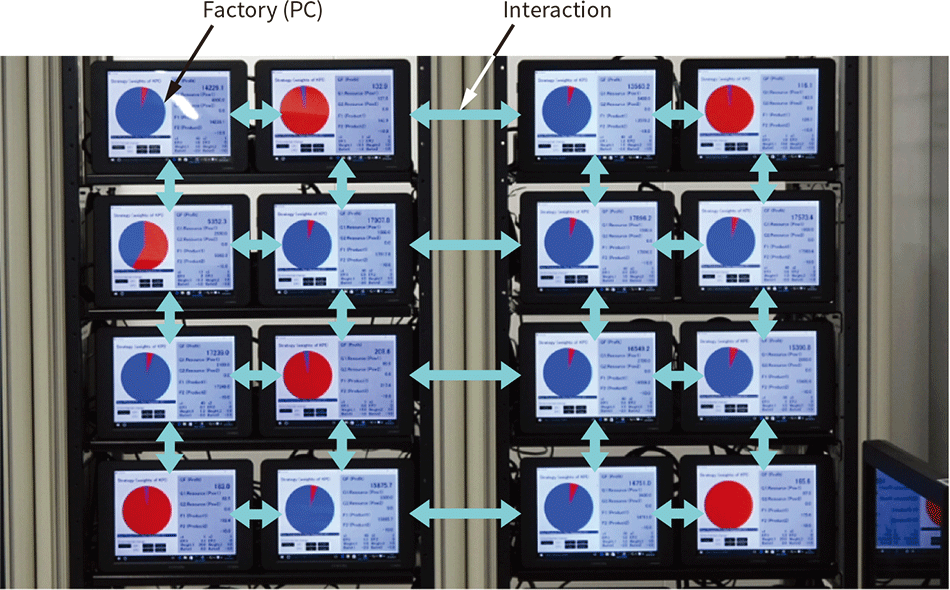

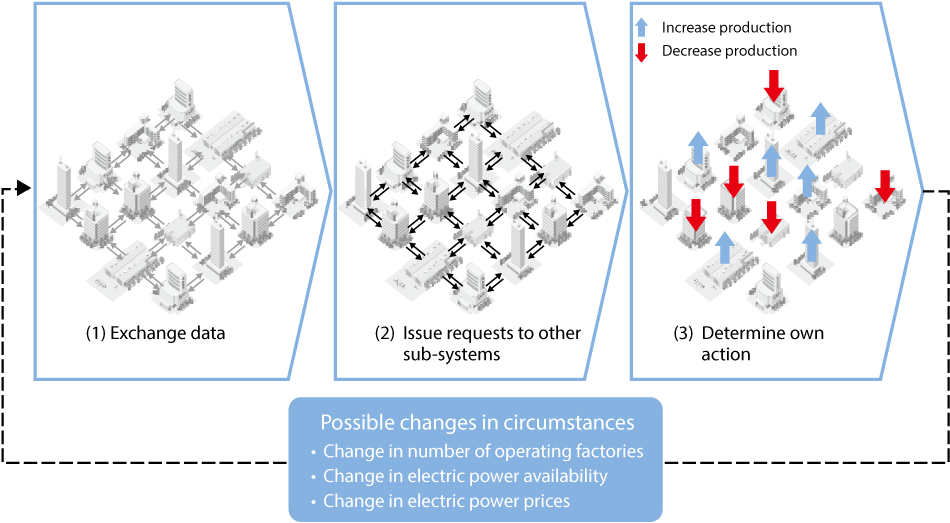

Taking note of this, Hitachi has developed a decentralized cooperative system made up of a large number of sub-systems that draws on the same principles of interaction as between animals engaged in collective behavior, without the need for a leader. The overall decentralized cooperative system corresponds to a flock, shoal, or herd of animals, while each sub-system corresponds to an individual bird, fish, or other animal. Whereas a centralized control system has a control center to aggregate all of the data in a single location and handle the calculations needed for system-wide optimization, the process of optimization in a decentralized cooperative system is distributed across the individual sub-systems. Each sub-system exchanges the necessary data with its neighbors such that system-wide optimization is achieved through the ongoing repetition of this process (see Figure 8.1). This significantly reduces the communication overhead associated with centralized data collection and the computational load of optimization, enabling real-time performance to be maintained even as the number of devices being controlled increases or in the event of unexpected changes in circumstances.

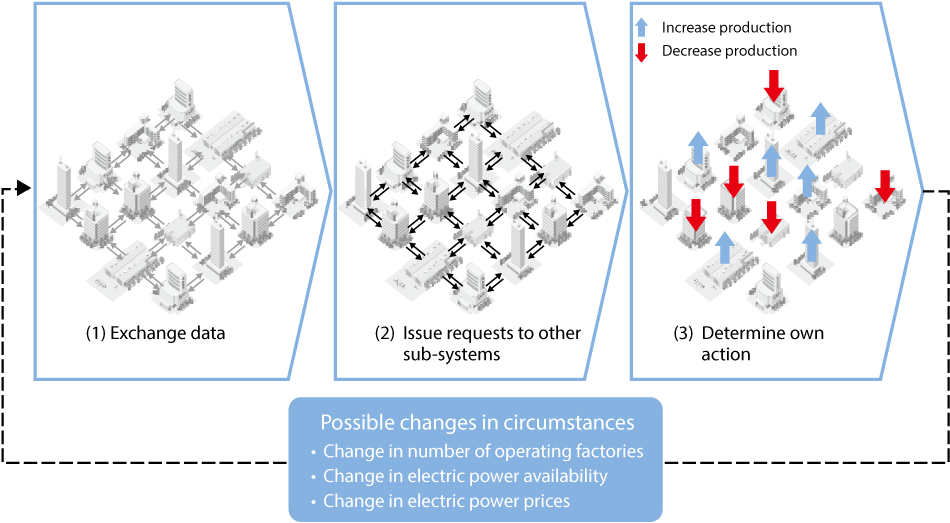

The system works by executing algorithms on the sub-systems that perform the following repetitive operations.

- Exchange data with other connected sub-systems.

- Based on this data, request other sub-systems to act in harmony.

- Execute the action requested by the greatest number of other sub-systems.

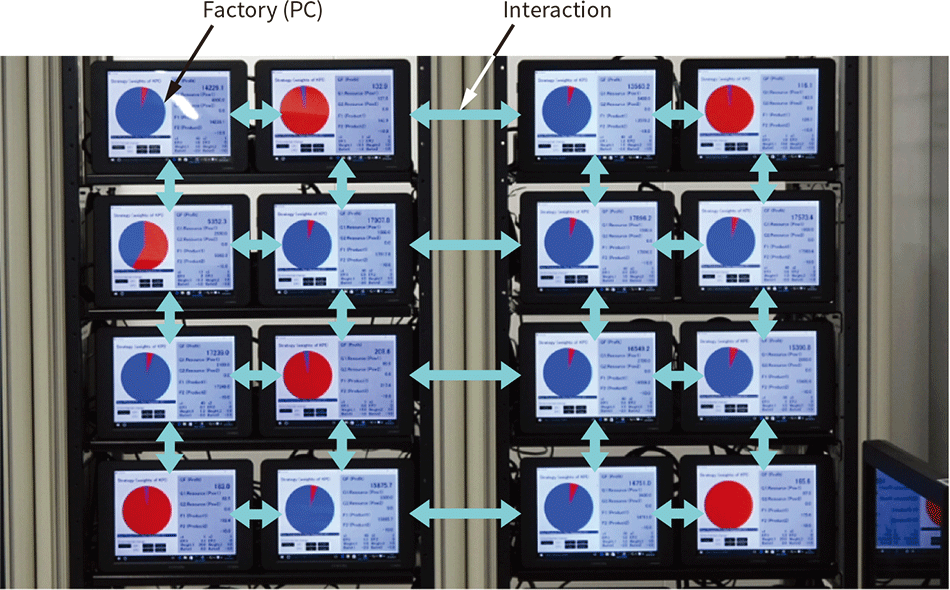

To test the effectiveness of the system, Hitachi has built a simulator that replicates a large group of factories, each of which is equipped with a production management system. Based on the exchange of data on production efficiency between the interconnected factories, the production management systems generate production plans by exchanging requests such that production is increased at sites where efficiency is high and reduced at sites where efficiency is low. The number of factories in the simulation was varied between 16 and 1,024 and their collective profitability was determined. The results indicated that the profitability would be the same as that achieved using centralized control. When a prototype environment simulating 16 factories was created, the amount of electric power supplied to the factories varied, and the resulting changes in profitability were measured, it was found that profitability equivalent to that of centralized control could be achieved 50-times faster (see Figure 8.2). This flexibility to handle the addition and removal of sub-systems and to adapt quickly to changes in circumstances means that the decentralized cooperative system also has potential applications in areas like supply chains and distribution systems as well as in production management systems.

In the future, Hitachi plans to contribute to the realization of Society 5.0 by further developing this technology, including through the use of AI and open innovation, so as to build social infrastructure systems that are able to operate autonomously and in harmony with humans and the environment.

7.1. Flowchart of production volume optimization using the decentralized cooperative system

7.2. Prototype decentralized cooperative system