Connective IndustriesResearch & Development

1. Digital Solution to Achieve Circular Economy Transformation for Industrial Products

The unsustainable "take-make-use-dispose" model necessitates a shift towards a circular economy (CE), focusing on extending product lifecycles through remanufacture, repair, reuse, and recycle (RE-X) processes. However, challenges like fragmented data and lack of visibility hinder widespread adoption.

Hitachi’s digital solution for industrial products circularity integrates a trusted data layer with RE-X domain-specific AI to address these challenges. Its technology innovations include circular demand-supply forecasting, returns forecasting, core condition and value assessment, and optimized sales and operations planning to balance economic and environmental key performance indicators (KPIs). This solution connects stakeholders, tracks products through value-chain and lifecycles, optimizes RE-X processes, and provides comprehensive KPIs to minimize waste and maximize resource utilization. Hitachi has validated the solution through successful proof-of-concept projects in the automotive and mining sectors. It is working with its digital businesses to offer the solution as a service, evolve it into a RE-X marketplace, and enable Hitachi’s product businesses to optimize their products for RE-X, contributing to a more sustainable future for industrial products in the growing $70B+ CE digital solutions market.

(Hitachi America Ltd.)

[01]Hitachi’s Digital Solution for Industrial Products Circularity![[01]Hitachi’s Digital Solution for Industrial Products Circularity](/rev/archive/2025/01/18/image/fig_01.png)

2. Digital Solution Framework for Enabling Electric Vehicle Battery Circularity

A circular economy for batteries is crucial for building a sustainable battery value chain, as end-of-life electric vehicle batteries can be given a second life or valuable raw materials can be harvested to make new batteries. However, significant challenges remain in forecasting availability, predicting remaining value, minimizing reverse logistics costs, and maximizing value recovery from end-of-life batteries. Hitachi has devised an ecosystem value optimization approach powered by a digital solution framework, consisting of innovative analytical models and a trusted data platform, to optimize five key value drivers for battery circularity—safety, regulatory compliance, carbon footprint reduction, quality, and financials. The envisioned solution can help reduce average transportation costs of end-of-life batteries by 11% to 44% compared to current shipping practices, estimate battery health with error rates less than 1%, and improve value recovery by 52% to 60% by routing batteries with good health to second-life application providers.

(Hitachi America Ltd.)

[02]Hitachi’s Solution Vision for Enabling Electric Vehicle Battery Circularity![[02]Hitachi’s Solution Vision for Enabling Electric Vehicle Battery Circularity](/rev/archive/2025/01/18/image/fig_02.png) IoT: Internet of Things

IoT: Internet of Things

3. Maximization of Electric Bus Performance: Optimal Charging Solutions to Minimize Battery Degradation

For battery-electric vehicle owners, a product lifetime of ten years or more is a crucial requirement for replacing internal combustion engine vehicles. However, there are instances where the battery life does not meet this requirement because of battery degradation caused by how the battery is charged and discharged. A solution to extend the battery life to a point where it aligns with the vehicle lifetime becomes necessary. Hitachi has developed measures to prolong battery life by regulating battery use during the vehicle lifetime, as shown by the three measures in Figure 1. First, the state of charge (SOC) range was optimized. If the SOC is too high, then degradation is accelerated. Second, the charging schedule was adjusted to avoid prolonged periods at a high SOC. Third, the optimal charging current rate and time based on battery characteristics were considered. Hitachi simulated the battery lifetime before and after applying these measures. The simulations shown in Figure 2 indicate that battery lifetime can be extended by about 25%.

(Hitachi Europe Ltd.)

4. Process Informatics Using Battery Inspection Data

With the electrification of mobility and the mainstreaming of renewable energy, demand for lithium-ion batteries as energy storage devices is rapidly increasing, and installation of new factories are being planned around the world. To improve yield during manufacturing, it is necessary to understand and finely control the correlation between design and manufacturing conditions. However, it can take considerable time for suppliers with limited knowledge to identify optimal conditions, becoming a major cause of startup delays.

Hitachi High-Tech and the Hitachi Research & Development Group are accumulating data on design and manufacturing conditions, intermediate product features, and final product performance in a database, and by using machine learning on these correlations, are developing a process informatics that supports the prediction of the final product performance and the determination of optimal process conditions. It has been demonstrated that combining easily obtainable top-view scanning electron microscope (SEM) observation with image analysis can extract the structural features of electrode sheets—an intermediate product, and prediction accuracy for product performance improved when these features were utilized as explanatory variables. Going forward, they aim to commercialize the technology after verifying its value through co-creation with stakeholders in battery manufacturing.

[04]Process Informatics in Battery Manufacturing (a) and Effect of Applying Structural Features on Battery Performance Prediction (b)![[04]Process Informatics in Battery Manufacturing (a) and Effect of Applying Structural Features on Battery Performance Prediction (b)](/rev/archive/2025/01/18/image/fig_04.png) MAE: mean average error

MAE: mean average error

5. Life Cycle Simulator for Transitioning to Circular Business Models

Hitachi and the National Institute of Advanced Industrial Science and Technology (AIST) have established a joint research hub, the Hitachi-AIST Circular Economy Cooperative Research Laboratory (H-AIST CE Lab.), with the aim of realizing a circular economy (CE) society. This focuses on building a grand design, the development of digital solutions, and the formulation of rules and standardization strategies. In the development of digital solutions, one of key challenges identified: companies struggle to choose the optimal path toward a circular economy due to the wide range of possible approaches. To address this, H-AIST CE Lab. has developed a life cycle simulator that enables simultaneous evaluation of environmental impact and business viability—for both the company and its stakeholders.

The simulator that H-AIST CE Lab. has created calculates material flows across the entire value chain, including inverse manufacturing processes, and quantifies associated greenhouse gas (GHG) emissions, revenue, and costs. It models and compares various circular economy strategies, and can be used to construct an optimal circular business model. Looking forward, Hitachi aims to enhance circularity in its own product businesses, and to deploy solutions to support a transition to circular businesses, in particular for business to business (B2B) products such as industrial machinery.

(H-AIST CE Lab.)

6. Life Cycle Design to Achieve Sustainable Manufacturing

Achieving products with a low environmental impact requires improving product design based on life cycle assessment (LCA). However, since LCA is typically performed after the product design phase, it is difficult to carry out simultaneously with design, meaning it is difficult to reduce the environmental impact. Accordingly, this study proposes a life cycle design approach that allows integrated evaluation of LCA, life cycle cost (LCC), and product performance during the early design phase. By referencing conventional product design data and presenting improvement scenarios for enhancing environmental performance, Hitachi is developing tools to support an eco design digital transformation (DX). The technologies developed in this study are as follows.

- “Design knowledge structuring technology” that uses generative AI to extract the relationships among requirement specifications, design indicators (quality, performance, environmental consideration), and design variables (material, dimensions, etc.) presented in the improvement scenarios from life cycle design, enabling an overview of design constraints and implementation proposals.

- “High-speed performance evaluation technology” that applies deep learning to conventional numerical simulation results, predicting product performance under design changes approximately 50 times faster than before, thereby supporting the balance of trade-offs among multiple KPIs.

[06]Life Cycle Design for Eco Design DX![[06]Life Cycle Design for Eco Design DX](/rev/archive/2025/01/18/image/fig_06.png) LLM: large language model

LLM: large language model

CNN: convolutional neural network

7. Blue Carbon Solutions for Balancing Environmental Restoration and Decarbonization

By using appropriate nutrient supply from sewage systems and industrial wastewater to maintain and expand seaweed beds, which serve as habitats for marine life and act as carbon sinks (blue carbon), Hitachi is working to create a blue carbon solution business that supports both healthy oceans and decarbonization.

As part of the "Nutrient Supply Management Project for Blue Carbon Promotion" launched through industry-government-academia collaboration to create a new business, discussions are underway with organizations possessing diverse expertise, and with stakeholders facing various challenges. At the same time, development is progressing on sewage treatment control technologies that flexibly respond to diverse water quality requirements, as well as measurement systems related to environmental conditions such as red tides and carbon storage. Furthermore, the development of a blue carbon cyber-physical system (CPS) to support appropriate nutrient supply management is also being advanced. Hitachi has started evaluating the blue carbon CPS using a hydrological-ecological model to assess how effluent discharge changes nutrient concentrations and impacts the environment. Lab-scale effluent addition tests and field trials in actual coastal waters both confirmed that larger brown algae grow more abundantly in seawater with higher nutrient concentrations.

Going forward, Hitachi will collaborate with a wide range of stakeholders to contribute to the restoration of marine environments and biodiversity, as well as to the achievement of a decarbonized society by 2050.

8. Designing a Vision for the Retail Supply Chain of 2035

The logistics and retail industries are facing significant challenges, including declining demand and severe labor shortages caused by population decline. In response, Hitachi has used its original content, such as “Kizashi (future signs) of an Economic Ecosystem,” which captures shifts in end-user values, to infer changes in consumer purchasing behavior and industry structure; together with internal and external experts, Hitachi has outlined a vision for the industry and proposed solutions for the year 2035.

The industry vision consists of four scenarios: (1) the transformation of essential goods into lifeline services and (2) the transformation of purchasing experiences into high-value-added services, which indicate the polarization of consumption behavior; (3) the diversification of the workforce and working styles; and (4) the revitalization of product and resource circulation in the retail sector, which is closely connected to final products. These emphasize the importance of creating systems that facilitate a virtuous cycle of goods and human resources without the problems of inefficiencies, waste, or imbalance.

Going forward, Hitachi will communicate this vision to the industry through visual materials and other means, and will work with corporate partners on-board with our vision to collaboratively realize each scenario.

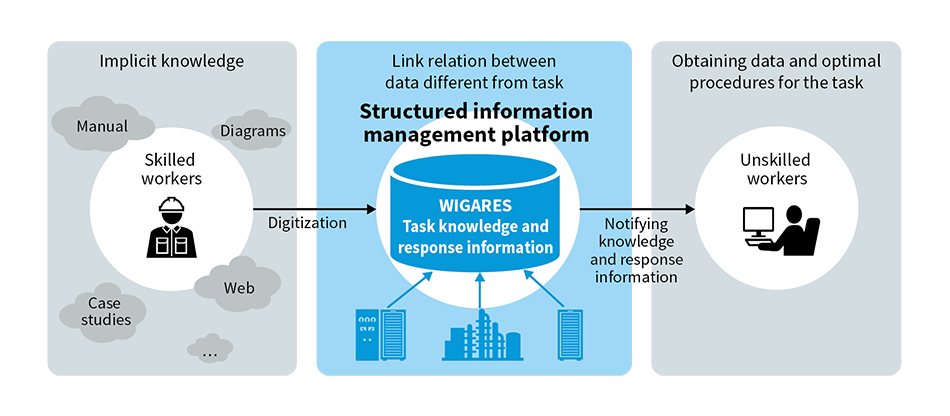

9. “WIGARES” Structured Information Management Platform

Industrial plants have the issue of keeping stable operations even in situations of worker shortages. To address the issue, Hitachi developed the “WIGARES”, structured information management platform, which digitizes the work-related know-how of experienced workers, and provides unskilled workers with necessary information by push notification.

Workflow analysis with a customer on abnormal events at a chemical plant revealed that an abnormality should be solved in its early stages because it could spread to downstream processes within a few hours from an alarm being triggered. WIGARES links an alarm with a correct response recorded by skilled workers, such as manuals, diagrams, case examples and web pages. Information referred to frequently is displayed prominently. Thereafter, if the same alarm occurs, the correct response is automatically notified to unskilled workers. As a result, unskilled workers could obtain the correct response in half the time, and contributions to stable plant operations could be expected.

10. Work Behavior Recognition Method Focusing on Local Motion and Posture

As the working-age population continues to decline, increased importance is placed on sustained productivity improvements. In response to this, work behavior recognition technology can be used to identify bottlenecks through task time measurement and ensure early detection of operational errors, thereby achieving efficient process improvements and resource optimizations. However, conventional behavior recognition methods require significant amounts of task data, leading to significant allocation of time and resources for data collection during on-site implementation.

Accordingly, Hitachi has developed a work behavior recognition method that enables learning using small amounts of data using workwear-typed sensors*. This technology uses Hitachi’s proprietary foundational model which has been pre-trained on localized generic movements and postures of each body part. Given that workplace tasks are recognized as combinations of these generic movements and postures, this minimizes the amount of data required at its implementation. An evaluation of recognition accuracy under small data conditions simulating actual workplaces showed a 7.4% improvement in task recognition accuracy by using the foundational model. Enabling learning from small datasets significantly reduces the cost of introducing work recognition technology, and is expected to accelerate real-world deployment.

[10]Acquired Skeletal Information and Local Motion and Posture![[10]Acquired Skeletal Information and Local Motion and Posture](/rev/archive/2025/01/18/image/fig_10.png)

11. Factory Configurator for Designing and Operating Robust Production Lines against Variability

There is increasing demand for the construction and updating of production lines accompanying increased investment in growth areas, against a backdrop of advances in smart manufacturing and automation technologies. In traditional mass production systems, maintaining the planned production efficiency was made possible by continuously producing the same product in fixed quantities over long periods. However, when developing adaptive production lines that can respond to market changes, challenges come to light regarding designing and operating lines that can accommodate variability in product types and demand, along with fluctuations in equipment and worker capabilities.

To address these challenges, Hitachi has developed a “Factory Configurator” to enable the design and operation of robust production lines that can handle such fluctuations. In production line design, use of a mathematical optimization method formulated as a mixed integer programming problem with complex combinations of production resources such as equipment and workers together with work processes enables rapid problem-solving in finding optimal line configurations. Additionally, in production line operation, the use of a variation prediction method based upon time-series analysis of operational data has enabled pre-generation of highly effective line modification plans.

By providing this Factory Configurator technology to internal and external production line managers, Hitachi is contributing to balancing constraints on capital investment, and reducing opportunity losses in production line design and operation.

[11]Application of Line Design and Operation for Factory Configurator![[11]Application of Line Design and Operation for Factory Configurator](/rev/archive/2025/01/18/image/fig_11.png)

12. High-reliability Mixed-load Depalletizing Technology Enabling Innovative Warehouse Automation

In order to ensure a stable labor force in logistics warehouses, there is a growing demand for automating physical tasks such as depalletizing. To expand the range of tasks suitable for automation, Hitachi has developed a robot control technology capable of handling mixed-load depalletizing scenarios, in which not only cardboard boxes but also wrapped items such as bottles and toilet paper rolls are stacked together.

Accurate recognition of items, when these are placed tightly together, is a real challenge in real-world environments. To address this, a recognition method has been developed that combines rule-based depth image processing with deep learning targeting boundary detection, utilizing luminance and depth images. This approach has achieved a 97.5% task success rate. A recovery method was also developed that evaluates the confidence level of the extracted boundaries. For items with low confidence, remote operators can provide handling instructions, enabling high-reliability operations that proactively prevent task failures.

Moving forward, Hitachi aims to improve task success rates and boundary confidence evaluation performance through on-site testing and validation, aiming to achieve early practical implementation.

13. Heterogeneous Transport System Synchronization Control Technology for Highly Efficient Collaboration between Transport Facilities

In industrial fields such as logistics and manufacturing, the introduction of automated transport equipment like automated guided vehicles (AGVs) is expanding throughout transport processes. To achieve efficient coordination between multiple systems provided by various vendors—each offering diverse automation solutions tailored to customer needs—Hitachi is developing a synchronization control technology for heterogeneous transport systems.

This technology generates operation plans that ensure transported items are delivered to handover operators in a timely manner across multiple transport processes. Specifically, it predicts the required travel time of each item to its destination and determines the transfer point and arrival timing at the handover point, thereby aiming to minimize operator idle time. To prevent delays in the execution of these plans at the start of each operation, this controls each transport system by prioritizing items based on their progress.

The application of this technology results in high productivity, along with an enhanced return on investment for customers adopting automation systems. Moving forward, Hitachi plans to apply this technology to real-world systems such as those for sorting within logistics warehouses, aimed at verifying its value and enabling early practical implementation.

[13]Heterogeneous Transport System Synchronization Control Technology![[13]Heterogeneous Transport System Synchronization Control Technology](/rev/archive/2025/01/18/image/fig_13.png) ST: station

ST: station

AGV: automated guided vehicle

14. Energy-saving Technology in the Newly Designed Oil-free Bebicon Compressor

The newly launched oil-free Bebicon from Hitachi Industrial Equipment Systems Co., Ltd. features a design that ensures stable performance even in environments 10°C hotter than previously, by employing a new “heat shield piston” with a spherical outer surface geometry. To enhance both the energy efficiency and reliability of this new piston—designed to oscillate in contact with the inner surface of the cylinder—the development team analyzed the outer edge contact angle, contact load, and sliding speed. With this, they identified the optimal cylinder offset and other values to maximize efficiency while also constructing a wear prediction model for the contact area, then performed multi-objective optimization balancing efficiency and minimization of wear.

Additionally, the valve configuration was reviewed, utilizing the piston’s rocking motion to release internal pressure, thus preventing air valve closing delays and allowing for a 14% increase in suction port area. These measures resulted in reduced heat loss from compressed air, lower pressure losses, a 3% increase in discharged air volume over the previous model, and improved startup performance. Additionally, the package type includes a new control function that adjusts unloading based on operating intervals, reducing power consumption by up to 15%.

(Released in April 2024)

[14]Piston/Cylinder Shape and Intake Valve Structure in the New Bebicon![[14]Piston/Cylinder Shape and Intake Valve Structure in the New Bebicon](/rev/archive/2025/01/18/image/fig_14.png)

15. Radial-gap Type Amorphous Motor

Power consumption of motors accounts for approximately 50% of global electricity consumption, making the improvement of motor efficiency a requirement in achieving carbon neutrality. Hitachi has developed a radial-gap type amorphous motor that can rotate at high speeds compared to conventional industrial motors, achieving significant improvements in efficiency along with size reductions.

Thin amorphous metal sheets, which lack a crystalline structure, can reduce core losses by about 90% compared to traditional materials, however their brittle and hard nature has made complex machining difficult. To address this, Hitachi has developed a new structure in which the motor core is segmented for simplicity, with amorphous metal applied specifically to the teeth area where energy losses are concentrated. In addition, new shaft support and cooling structures were developed to suppress the vibration and heat generation associated with high-speed operation of the motor, achieving both high speed and high efficiency. A 55 kW prototype developed for air compressors achieved over 95% efficiency (equivalent to IE5*1 standard) at a rated speed of 20,000 r/min, and was successfully downsized to one-fifth the size of conventional models.

This achievement earned the 2023 NEDO Energy Conservation Technology Development Award.*2) In the future, Hitachi aims to apply this technology to a wide range of industrial equipment, including high-speed air compressors, thereby contributing to energy savings and decarbonization.

- *1

- The highest level in the international standards for the energy efficiency of motors set by the International Electrotechnical Commission (IEC).

- *2

- Part of this research was carried out as a component of the New Energy and Industrial Technology Development Organization’s (NEDO) program into the research, development, and social implementation of energy-saving technologies aimed at realizing a decarbonized society, specifically regarding the development of ultra-high-efficiency utility drive systems.

16. Laser Differential Interference Measurement for Detecting Low-step-height Defects on Semiconductor Wafers

On the back of strong global investment in AI-related fields, the semiconductor market continues to grow, and so the stable supply of semiconductor devices and wafers—their base materials—is more critical than ever. In semiconductor production lines, optical inspection equipment is essential for improving yield.

Hitachi High-Tech Corporation’s LS series inspects wafers by irradiating the surface with laser light, and detecting scattered light from microscopic foreign matter. However, in recent years, there has been a growing need to detect low-step-height defects*, a task difficult using conventional scattered light methods. To address this, a differential interference measurement system was developed, comprising an optical system that splits laser light into two beams using a polarization separation element and detects the resulting interference signal, and an algorithm that reconstructs defect shapes based on that interference signal. Hitachi has confirmed that this system is capable of detecting low-step-height defects just a few nanometers in height, and it has been implemented in the LS9300AD, released in March 2024.

- *

- Defects that gradually vary across a nanometer-scale height and micrometer-scale width.

[16]Laser Differential Interference Measurement Enabling Detection of Low-step-height Defects on Semiconductor Wafers![[16]Laser Differential Interference Measurement Enabling Detection of Low-step-height Defects on Semiconductor Wafers](/rev/archive/2025/01/18/image/fig_16.png) AFM: atomic force microscope

AFM: atomic force microscope

17. In-line Electrical and Material Property Measurement Technology to Improve Semiconductor Productivity

The number of process steps in semiconductor manufacturing continues to increase, and there is an urgent need to improve productivity. Traditionally, production lines have featured scanning electron microscope (SEM)-based dimension measurements and defect inspections—these have played a key role in stabilizing production within the production lines. However, with the advent of 3D device structures and increasing material diversity, there is an increase in defects in internal circuits or materials within the wafer undetectable by conventional in-line inspection and measurement methods, and accordingly there is growing demand for next-generation inspection and measurement technologies.

To meet this need, Hitachi is developing laser-assisted SEM (LA-SEM). This inspects and measures electrical and material properties by irradiating samples with lasers and analyzing their responses to electron and light exposure. This technology enables the measurement of electrical properties such as capacitance, along with obtaining contrast that reflects changes in material properties. Specifically, for example, it enables the quantitative measurement of plasma processing damage to SiO2 films. Moving forward, the goal is to expand the range of measurable indicators available on the production line, aiming for higher precision in process control for advanced semiconductor manufacturing.

[17]Schematic of LA-SEM (a) and Example of Material Property Measurement (b)![[17]Schematic of LA-SEM (a) and Example of Material Property Measurement (b)](/rev/archive/2025/01/18/image/fig_17.png)

18. Sub-nanometer-scale Height Measurement of Copper Electrodes

As semiconductor integration becomes more three-dimensional, the adoption of hybrid bonding processes is accelerating. This process forms copper electrode patterns with height variations on the order of a few nanometers on wafer surfaces. These are then directly bonded together to achieve high-speed, high-density electrical connections between two wafers. The connection of the copper electrodes depends heavily on the pattern step, making it essential to measure such variations with high precision in mass production environments.

To meet this need, Hitachi has developed a technology for measuring heights in low-step sections using a scanning electron microscope (SEM) equipped with four azimuthally arranged backscattered electron detectors. Specifically, this method models the relationship between the surface slope of the sample and the intensity of backscattered electrons, taking into account the actual characteristics of the equipment. This uses shading information from across multiple detector images to derive an indicator that correlates with the heights. The technology was evaluated in collaboration with imec*), an international research institute in Belgium, and showed promise in measuring copper electrode step heights with sub-nanometer precision.

As copper electrodes continue their miniaturization and increase in density, management of step height is likely to become increasingly important. We will promote the practical application of this so that it can become a valuable evaluation metric in both the development and control of hybrid bonding processes.

- *

- One of the world’s largest semiconductor research and development institutions, headquartered in Leuven, Belgium. It collaborates with universities and companies around the world to develop next-generation electronics technologies such as lithography, solar cell, and organic electronics technologies.

[18]Height Measurement Using Four-azimuth Scanning Electron Microscope Images![[18]Height Measurement Using Four-azimuth Scanning Electron Microscope Images](/rev/archive/2025/01/18/image/fig_18.png)

19. Rapid Infectious Disease Testing Technology to Combat the Threat of Drug-resistant Bacteria

There is an urgent need worldwide to combat drug-resistant bacteria which are resistant to antibiotics. To control the spread of drug-resistant bacteria, it is essential to administer appropriate antibiotics tailored to the specific bacterial strain causing the infection. Until now, identifying bacteria has relied on culture-based methods, which require that the bacteria be grown for about two days before testing.

Hitachi is therefore developing high-sensitivity rapid diagnostic technology using genetic analysis, aiming to drastically shorten this testing time. The key technologies developed so far are as follows.

- Polymerase chain reaction (PCR) with rapid thermal cycling using surface plasmon resonance heating and forced cooling with compressed air, allowing fast amplification of bacterial genes.

- A flow-type microarray technology that uses turbulent flow inside a microchannel to rapidly bound amplified genes to specific detection spots, which then detects the presence or absence of target genes using fluorescence.

In the future, by combining these technologies, Hitachi aims to provide medical facilities with a system that enables the identification of bacterial strains on the same day as testing, thereby helping optimize the use of antibiotics.

20. Large-scale Production of Actinium-225 for Targeted Alpha Therapy, Provision of Research Samples

Targeted alpha therapy (or alpha-particle based radioligand therapy) is an emerging cancer treatment that uses radiopharmaceuticals—a combination of radioactive isotopes that emit alpha particles, with drugs that selectively accumulate in cancer cells. Among potential isotopes for this treatment method, Actinium-225 (Ac-225) shows high promise. However, there is an extremely limited global supply, with an urgent desire to achieve large-scale production as soon as possible. Up until now, Hitachi has been working to develop a high-efficiency, high-quality production method for Ac-225 using an electron linear accelerator.

Through joint research with Tohoku University, Hitachi has developed technology to handle radium, the raw material, and an irradiation system for the accelerator. They have succeeded in demonstrating production of 50 MBq of Ac-225, sufficient for research use, and have started providing samples to pharmaceutical companies and research institutions. Additionally, joint research with the National Cancer Center Japan confirmed that the Ac-225 produced was of adequate quality for non-clinical studies. Going forward, Hitachi aims for the early practical implementation of this production technology through collaborative research with companies and research institutions that have received samples, contributing to the conquest of cancer and the improvement of quality of life (QoL) for cancer patients.

21. Development of Energy Simulation Technology for Achieving Zero-energy Buildings

The building sector accounts for 46% of annual energy consumption and 51% of annual carbon emission in China (2020). Promoting energy conservation and carbon emission reduction in buildings is crucial for achieving the dual carbon goals. Building performance simulation, as a digital technology, plays an important role in the analysis and optimization of building energy consumption quantitatively. On the basis of Hitachi’s electric products, building management system and artificial intelligence (AI), building simulation technology is developed to simulate dynamic energy generation and consumption with the digital twin of the building comprising envelope thermal insulation, dynamic equipment performance, and dynamic thermal load from people flow, lights, and facilities, etc. It enables the evaluation and optimization of control strategies for equipment operation towards minimization of net-energy consumption and electricity cost reduction under dynamic electricity pricing without deteriorating human thermal comfort. The optimization cycle also incorporates AI prediction technology based on historical operation data. This simulation technology is expected to contribute to Hitachi’s building solutions in achieving zero-energy buildings.

[Hitachi (China) Ltd.]

[21]Building Energy Simulation Schematic![[21]Building Energy Simulation Schematic](/rev/archive/2025/01/18/image/fig_21.png) HVAC: heating, ventilation and air conditioning

HVAC: heating, ventilation and air conditioning

22. Development of Biomass Composite Materials Using Low-environmental-impact Plant-based Resources

Environmental pollution caused by petroleum-derived plastic materials has become a major social issue, and so biomass composite materials made by blending plant-based polysaccharides with resins are garnering increased attention as alternative materials with a lower environmental impact. In composites containing polysaccharides, failure of the interface between the polysaccharide and resin leads to a decrease in impact strength, making improving interfacial adhesion a key challenge.

This study focused on starch, a representative example of polysaccharides, and devised a method to use molecular dynamics (MD) simulations to evaluate the molecular-level adhesion state at the interface between starch and various resins. As a result, resins with high adhesion to starch were identified, with the chemical structures responsible for that adhesion being clarified. In addition, an ester-modified structure of starch was derived that exhibits high affinity when associated with resin. Materials were then prepared based on recipes predicted through simulation. These showed suppressed interface breakdown between the starch and resin, with an approximately 2.5-times increase in impact strength. The molecular-level design insights obtained through this research are expected to be valuable for deriving recipes for a wide range of biomass composite materials where the compatibility between the constituent materials is an issue, thus contributing to broader application.

[22]Materials Recipe Development Using MD Simulation![[22]Materials Recipe Development Using MD Simulation](/rev/archive/2025/01/18/image/fig_22.png) PLA: polylactic acid

PLA: polylactic acid

PBS: polybutylene succinate

PBAT: polybutylene adipate terephthalate

PHB: polyhydroxybutyric acid

TPS: thermoplastic starch

E-TPS: esterified TPS

23. Automatic Installation Robot for Elevator Construction

Elevator installation involves handling heavy components in high, confined spaces, placing significant physical and mental strain on workers. Among these tasks, the installation of guide rails is particularly important, as it directly affects ride comfort, therefore it requires high-precision positioning work. Hitachi is developing a robot that automatically installs guide rails, utilizing the mechatronics and robotics expertise it has cultivated in the industrial sector, with the aim of using automation to reduce the burden on workers, and enhance safety.

During guide rail installation, positioning is performed using the relative distance to vertical piano wires installed within the hoistway, with guide rails being fixed to the hoistway wall at regular intervals using support brackets. The installation robot repeatedly performs alignment of the guide rail supports, drilling into the wall, and fastening with screws, using its arm and a proprietary piano wire position detection sensor. To ensure good elevator ride quality, it is crucial to accurately determine the robot’s position and orientation within the hoistway. The developed piano wire position detection sensor uses cameras to capture images of the piano wire from two perpendicular directions, enabling it to calculate the relative position between the thin wire and the sensor. This information is used to generate movement commands for the robot arm, providing high-precision positioning of guide rails and accurate attachment of support brackets to the hoistway wall.

In the future, Hitachi will use this installation robot at actual construction sites, helping bring about safe and highly efficient construction sites.

24. Design of the Next-generation Standard Elevator

In response to the diversifying and increasingly specialized needs of users, Hitachi has collaborated with NAOTO FUKASAWA DESIGN LTD., led by world-renowned product designer Naoto Fukasawa to develop the Urban Ace HF Plus with the aim of creating a standard-type elevator that will become the next-generation global standard. This model follows the philosophy embodied in the 2015 flagship model HF-1, of “fully eliminating ornate designs and expressive forms used for conveying information, achieving a ‘true comfort’ allowing effortless, unconscious movement.”

While being a cost-competitive standard model, the HF Plus aspires to establish a new standard that rivals custom-made elevators in their attention to detail, and that accommodates a wide range of user needs. Its design balances high flexibility with refined aesthetics, and has been highly acclaimed both in Japan and internationally, earning five major design awards including the iF Design Award 2022 (Germany).

25. Building Solution Platform BuilMirai and Service Infrastructure Operation Technology

The BuilMirai building solution platform uses a microservices architecture to provide flexible service configurations tailored to diverse user requirements. However, due to this architecture, functionality is distributed across multiple environments such as cloud systems and on-site devices, making it challenging to monitor the operation status and detect faults of a service that operates by combining distributed functions. To address this, Hitachi has developed an end-to-end (E2E) monitoring technology that enables monitoring of complex services operating across multiple environments, with the goal of delivering high-reliability services.

This E2E monitoring technology includes trace technology that tracks function calls in response to changes in service configuration, and can handle cross-environment tracking by passing call sequence information between the cloud and on-site devices [(1) in the diagram]. As a result, processing data from both the cloud and the on-site devices are linked together [(2) in the diagram] into a single stream of information. By analyzing this data, the system can monitor the operational status and detect faults in complex services that span multiple environments.

This technology enables monitoring of the operational status and faults in building solutions with service components distributed across multiple environments in response to user requirements, thereby contributing to the delivery of highly reliable services.

26. “exiida” Cloud-based Control of Air Conditioning Energy Consumption

The Japanese government has announced its goal to reduce greenhouse gas emissions by 46% by FY2030 (compared to FY2013) as part of its measures to combat global warming. Focusing on the fact that air conditioning accounts for a large portion of power consumption in office buildings, Hitachi has developed a new method to control building air conditioning systems from the cloud, enabling adjustment of energy consumption.

Traditional control methods often reduced energy consumption by stopping the air conditioning units, but this approach significantly compromised comfort and made precise control of energy consumption difficult. The newly developed method, however, uses AI-based control to accurately adjust energy consumption while maintaining comfort, by predicting energy use based on the room temperature, power consumption, and weather information data from each indoor unit.

This technology is applied in the “exiida” IoT air conditioning service offered by Hitachi Global Life Solutions, Inc., contributing to reduced electricity costs for customers.

27. Efficiency-increasing Technology for CO2 Scroll Compressors for Water Heaters to Meet New Top Runner Standards

In households, 27% of energy consumption is used for water heating, making energy savings in water heaters essential to achieving carbon neutrality. Hitachi offers the EcoCute eco-friendly residential heat pump water heater that uses CO2 refrigerant, with the key focus being on performance improvements to the compressor, given that this accounts for 80% of total power consumption.

To achieve higher compressor efficiency at a low cost, Hitachi targeted reductions in discharge pressure loss and oil agitation loss at the outer edge of the orbiting scroll plate, without making any major structural changes. To reduce the discharge pressure loss, Hitachi added a notch to the center tooth tip of the fixed scroll, and a counterbore hole at the center of the orbiting scroll plate, thereby maximizing the cross-sectional area of the discharge flow path. In reducing oil agitation losses, oil compression prevention grooves were added to the outer periphery of both the fixed scroll plate and the frame, opposite the orbiting scroll, to prevent oil compression.

This configuration improved compressor efficiency by 1.4% under 65°C winter conditions, and this has been adopted in two EcoCute models released by Hitachi Global Life Solutions, Ltd. in November 2024.

![[03-1]Charging Measures to Extend Battery Lifetime](/rev/archive/2025/01/18/image/fig_03-1.png)

![[03-2]Effect of Charging Measures](/rev/archive/2025/01/18/image/fig_03-2.png)

![[05]Life Cycle Simulator Calculation](/rev/archive/2025/01/18/image/fig_05.png)

![[07]Blue Carbon Solutions](/rev/archive/2025/01/18/image/fig_07.png)

![[08]Vision for the Retail Supply Chain of 2035](/rev/archive/2025/01/18/image/fig_08.png)

![[12]Prototype Mixed-load Depalletizer Robot](/rev/archive/2025/01/18/image/fig_12.png)

![[15]Developed Motor Exterior and Core Configuration](/rev/archive/2025/01/18/image/fig_15.png)

![[19]Rapid Bacterial Testing Technology under Development](/rev/archive/2025/01/18/image/fig_19.png)

![[20]Targeted Alpha Therapy Using Actinium-225](/rev/archive/2025/01/18/image/fig_20.png)

![[23]Automatic Installation Robot under Development](/rev/archive/2025/01/18/image/fig_23.png)

![[24]Urban Ace HF Plus Entrance and Interior](/rev/archive/2025/01/18/image/fig_24.png)

![[25]E2E Monitoring Spanning Multiple Environments](/rev/archive/2025/01/18/image/fig_25.png)

![[26]Cloud-based Building Air Conditioning Control Method](/rev/archive/2025/01/18/image/fig_26.png)

![[27]CO<sub>2</sub> Scroll Compressor for Hot Water Heater](/rev/archive/2025/01/18/image/fig_27.png)