Hitachi’s Efforts in the Nuclear Sector (2)Development of New Reactor Designs by Hitachi-GE Nuclear Energy

Highlight

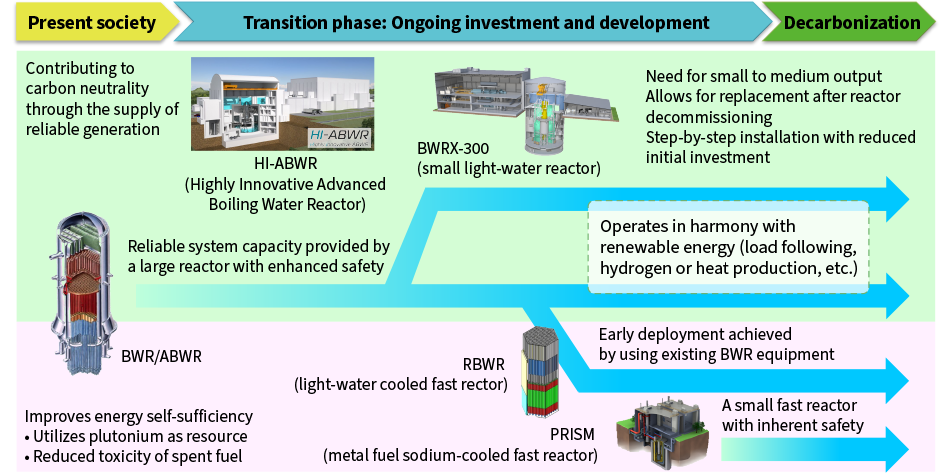

Hitachi-GE Nuclear Energy, Ltd. is adopting a step-by-step approach to develop four reactor designs that provide diverse solutions to meet societal needs. These designs include the innovative light-water reactor, HI-ABWR, the small light-water reactor, BWRX-300, the light-water-cooled fast reactor, RBWR, and the sodium-cooled fast reactor, PRISM. The HI-ABWR is being developed as an “innovative light-water reactor” in the Cabinet Decision on the "Basic Policy for Realization of GX" in February 2023 in Japan. The BWRX-300 is being established as a globally standardized design, considering the movements for deployment in Canada, the United States, and other countries. The RBWR utilizes proven light-water cooling technology to realize a fast reactor, while the PRISM achieves both inherent high safety and economic efficiency by adopting innovative technology.

This article describes these four reactor designs that share a goal of contributing to carbon neutrality.

1. Introduction

Figure 1—Hitachi-GE Nuclear Energy’s Reactor Development Strategy BWR: boiling water reactor, ABWR: advanced BWR, HI-ABWR: highly innovative ABWR, RBWR: resource renewable BWR, PRISM: Power Reactor Innovative Small ModuleThrough its development of new reactor designs, Hitachi-GE Nuclear Energy is taking a step-by-step approach to deliver diverse solutions.

BWR: boiling water reactor, ABWR: advanced BWR, HI-ABWR: highly innovative ABWR, RBWR: resource renewable BWR, PRISM: Power Reactor Innovative Small ModuleThrough its development of new reactor designs, Hitachi-GE Nuclear Energy is taking a step-by-step approach to deliver diverse solutions.

Efforts to achieve carbon neutrality have accelerated in recent years, with over 150 nations and regions committing to reaching this goal by 2050 (or by 2070 in some cases). Nuclear power is widely seen as a key source of decarbonized energy essential for achieving carbon neutrality. At the 28th United Nations Climate Change Conference (COP28) in December 2023, a cooperative strategy was announced to triple the global installed capacity of nuclear power plants by 2050 compared to 20201), *1.

Hitachi-GE Nuclear Energy is developing and commercializing four new reactor designs to address the growing global needs for nuclear power, drawing on over 40 years of experience in constructing boiling water reactors (BWRs) and fuel cycle technology. These are the Highly Innovative Advanced Boiling Water Reactor (HI-ABWR)2), an innovative large-scale light-water reactor that will contribute to achieving carbon neutrality in the relatively near future as a highly reliable installed capacity; the BWRX-300, a highly economical small module light-water reactor; the Resource-renewable BWR (RBWR), a light-water-cooled fast rector designed to enhance future energy self-sufficiency; and the Power Reactor Innovative Small Module (PRISM), an innovative small sodium-cooled fast reactor (see Figure 1). Hitachi-GE Nuclear Energy is taking a step-by-step approach to delivering diverse solutions to meet societal needs, considering the features of each reactor design and the progress of implementation studies. The following sections describe the characteristics of these four new reactors and the ongoing efforts for their development.

- *1

- Ratified by Japan and 30 other nations, as of November 2024.

2. HI-ABWR (Innovative Light-water Reactor)

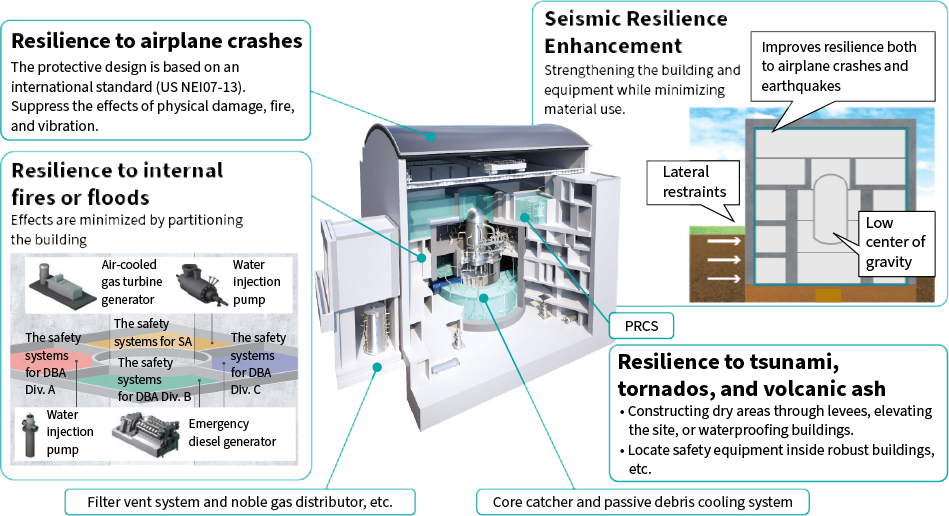

Figure 2—HI-ABWR overview and Improvements to Resilience against External and Internal Hazards NEI: Nuclear Energy Institute, PRCS: passive reactor cooling system, SA: severe accidents, DBA: design basis accidents While in recent years measures have been improved to enhance resilience against external hazards like large airplane crashes at nuclear power plants, layout design will also consider internal hazards and site conditions.

NEI: Nuclear Energy Institute, PRCS: passive reactor cooling system, SA: severe accidents, DBA: design basis accidents While in recent years measures have been improved to enhance resilience against external hazards like large airplane crashes at nuclear power plants, layout design will also consider internal hazards and site conditions.

Work is ongoing on the commercialization of the HI-ABWR with the goal of using large reactors to ensure reliable installed capacity. The HI-ABWR is an innovative light water reactor based on the internationally standardized ABWR, which has already received design certification in the UK. It integrates safety enhancements based on the lessons learned from the Fukushima Daiichi nuclear power plant accident. The electric power of the HI-ABWR is planned to be 1,350 to 1,500 MWe, and the measures for design basis accidents are basically the same as the conventional ABWR, such as the engineered safety feature with three divisions of emergency core cooling system. It also incorporates innovative safety features, including enhanced protection for safety systems against natural disasters, terrorism, and internal hazards. A passive reactor cooling system (PRCS) improves decay heat removal during an accident while a core catcher and passive debris cooling systems effectively manage a melting core. Additionally, it has a radioactive substance containment system with a noble gas distributor, which significantly reduces the need for nearby residents to evacuate in the event of a severe accident3). This distributor also enables the more rapid release of hydrogen, thereby reducing the risk of hydrogen combustion.

The HI-ABWR is improving plant design and nuclear safety while using existing designs. The reactor building has been strengthened without excessively increasing the material used by using its outer walls as both seismic-resistant walls and protection against external physical damage from natural disasters or airplane crashes. Seismic resilience enhancement includes lateral restraints at the underground levels of the building and the low center of gravity of the reactor building, a characteristic of the ABWR. To improve resilience to events that lead to common cause failures, the interior of the reactor building is divided into four divisions with fire-resistant and water shut off walls in case of fires or floods(see Figure 2). Passive safety systems, PRCS, and passive debris cooling system minimize the need for operator intervention and eliminate dynamic equipment like pumps, enhancing response reliability during an accident and preventing its escalation. Regarding radioactive substance containment systems, a noble gas distributor will be added downstream of the conventional filter vent system to suppress the release of radioactive substances during venting. The work to implement the HI-ABWR will continue to further refine the plant design and improve its safety.

3. BWRX-300 (Light-water SMR)

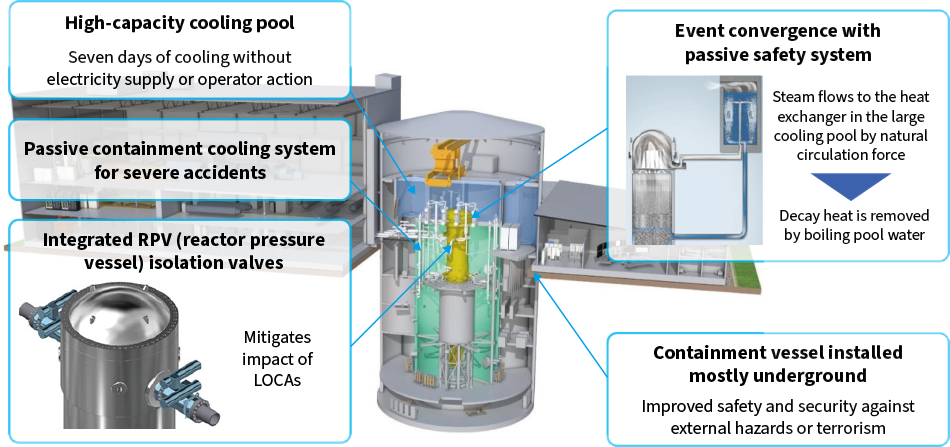

While the value of nuclear power generation is being re-evaluated as society needs to achieve carbon neutrality, deregulated electricity markets call not only for lower generation cost, but also for low investment risk by reducing construction cost. This has led to international interest in small modular reactors (SMRs) and Hitachi-GE Nuclear Energy is developing the 300-MWe BWRX-300 small light-water reactor in partnership with its sister company, GE Hitachi Nuclear Energy. While it is said that small reactors have scale demerits, simplification of the plant systems on the BWRX-300 should overcome this disadvantage while also enhancing safety, with the design being based on an advanced reactor concept featuring reactor pressure vessel isolation valves that effectively mitigate the impacts of loss-of-coolant accidents (LOCAs). Simplification of the plant systems improves reliability and reduces operation and maintenance costs by reducing the number of components used in the plant while also reducing the amount of waste with when decommissioning. Recognizing these benefits, an application for construction approval is currently in progress in Canada with the goal of commencing plant operation as early as 2029 at Ontario Power Generation (OPG), an electric power company in Ontario, Canada4). As there is also interest in deploying BWRX-300s in the USA and Europe, GE Hitachi has started work on developing a standard design in partnership with OPG, the Tennessee Valley Authority (an electric power company in the USA), and Synthos Green Energy of Poland5). Hitachi-GE Nuclear Energy is also working toward the early commercialization of the BWRX-300 by drawing on its accumulated skills and experience to partner with GE Hitachi Nuclear Energy in areas such as testing key technologies and designing major items of equipment. Development will continue with a view to deploying BWRX-300 plants in Japan also.

Figure 3—BWRX-300 Concept LOCA: loss-of-coolant accidentUse of an innovative reactor design featuring integrated isolation valves mitigates the impacts of loss-of-coolant accidents (LOCAs). The design uses passive safety systems that can operate without mains electric power or operator input.

LOCA: loss-of-coolant accidentUse of an innovative reactor design featuring integrated isolation valves mitigates the impacts of loss-of-coolant accidents (LOCAs). The design uses passive safety systems that can operate without mains electric power or operator input.

4. RBWR (Light-water-cooled Fast Rector)

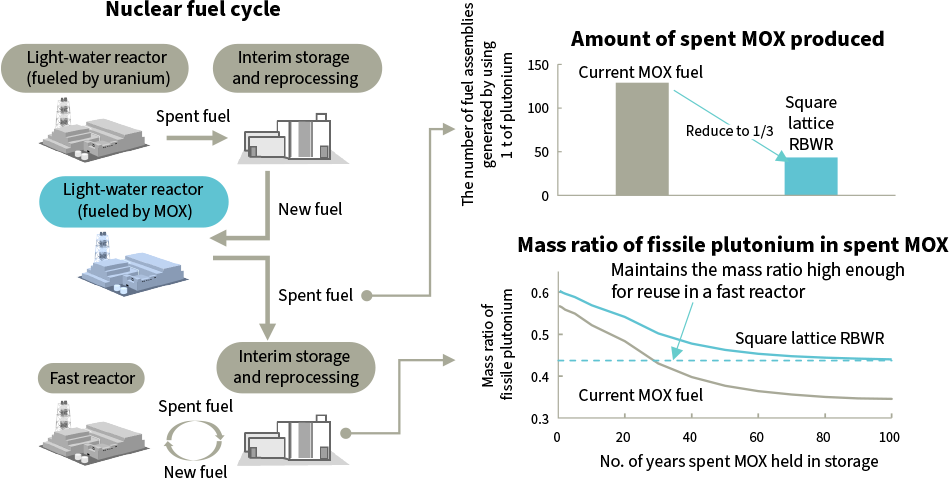

Beyond making the most of existing light-water reactors, if nuclear energy is to be a sustainable source of energy there will be a need in the future to transition to fast reactors that can utilize the plutonium present in the light-water reactor spent fuel. While spent fuel needs to be reprocessed to reduce its volume and control stockpile sizes, non-proliferation concerns require that the plutonium recovered by reprocessing be consumed in light-water reactors until the deployment of fast reactors in the latter half of this century.

Hitachi-GE Nuclear Energy is developing the RBWR as a fast reactor with light-water cooling that can achieve performance similar to a sodium-cooled fast reactor by exploiting the characteristic boiling of cooling water (neutron moderator) that occurs in BWRs. To speed up deployment, existing light-water reactors are currently being retrofitted based on this concept and efforts are going into the development of a fuel suitable for burning plutonium that can be used until fast reactors become available (square lattice RBWR). The square lattice RBWR reduces the quantity of spent mixed oxide (MOX) fuel generated by burning plutonium and allows reprocessing to achieve a greater reduction in the volume of spent fuel. Moreover, by minimizing degradation of the plutonium isotopic composition that results from burning the fuel in light-water reactors and from the long-term storage of spent fuel, it will allow for better reuse of the plutonium from spent fuel in fast reactors when they become available, even if that takes longer than expected. This provides more flexibility in the transition from light-water to fast reactors.

Figure 4—Anticipated Nuclear Fuel Cycle and Benefits of Square Lattice RBWR MOX: mixed oxideThis plan encourages the use of plutonium and allows reprocessing to achieve a greater reduction in the volume of spent fuel. In addition to reducing the amount of MOX spent fuel that is produced, this also smooths the transition to a fast reactor fuel cycle by minimizing degradation of the residual plutonium composition in the MOX spent fuel.

MOX: mixed oxideThis plan encourages the use of plutonium and allows reprocessing to achieve a greater reduction in the volume of spent fuel. In addition to reducing the amount of MOX spent fuel that is produced, this also smooths the transition to a fast reactor fuel cycle by minimizing degradation of the residual plutonium composition in the MOX spent fuel.

5. PRISM (Sodium-cooled Fast Reactor)

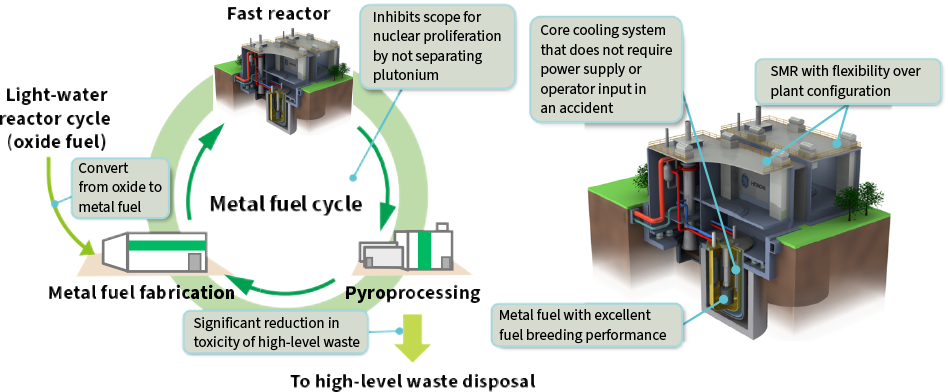

Japan is promoting a nuclear fuel cycle policy that will reduce the amount and toxicity of high-level radioactive waste and maximize the use of resources. Hitachi-GE Nuclear Energy is also collaborating on the conceptual design of a demonstration fast reactor to commence operation in the 2040s. Meanwhile, the metal fuel cycle, which combines small metal-fueled fast reactors with small-scale pyroprocessing and fuel fabrication, can simultaneously recover plutonium (Pu) and minor actinides (MA) without separating them for reuse as fuel, providing high proliferation resistance and utilize a high density of heavy metals and average neutron energy of metal-fueled fast reactors core to demonstrate transmutation technology to minor actinides at an early stage. To this end, development work has been underway, it aims to introduce the PRISM6) SMR concept (311 MWe per unit) developed by GE Hitachi Nuclear Energy to Japan.

The PRISM is a fast reactor that uses a passive safety system facility to achieve core cooling without power supply and operation during an accident, and metal fuel with inherent safety features, etc. In addition, a flexible plant configuration is possible due to the number of modules that can be installed to reduce the initial investment. Moreover, in the USA, GE Hitachi Nuclear Energy is working with TerraPower, LLC on the Natrium*2 Project to build a demonstration plant using PRISM technology, with construction commencing in June 2024 to operation around 2030. The system is a design option that responds to load variability, including renewable energy output variability, by combining the fast reactor with a molten salt thermal storage system that store or release extra heat according to the demand for electricity. Hitachi-GE Nuclear Energy intends to develop the technology while also conducting feasibility studies in cooperation with the USA and Japan partners on compliance with Japan’s regulatory requirements and implementing the metal fuel cycle in the future.

- *2

- Natrium is a trademark of TerraPower, LLC.

Figure 5—Overview of Metal Fuel Cycle and PRISM Fast Reactor PRISM is a fast reactor that uses metal fuel (U-Pu-Zr) in its core, typically comprised of two nuclear modules and one turbine device in a single power block set. The diagram above shows the standard nuclear reactor module (provided by GE Hitachi Nuclear Energy). The Integral Fast Reactor (IFR) concept has been developed that integrates metal fuel fast reactors, pyroprocessing and fuel fabrication into a facility.

PRISM is a fast reactor that uses metal fuel (U-Pu-Zr) in its core, typically comprised of two nuclear modules and one turbine device in a single power block set. The diagram above shows the standard nuclear reactor module (provided by GE Hitachi Nuclear Energy). The Integral Fast Reactor (IFR) concept has been developed that integrates metal fuel fast reactors, pyroprocessing and fuel fabrication into a facility.

6. Conclusions

This article reports on the development progress and implementation studies of the HI-ABWR, BWRX-300, RBWR, and PRISM reactor designs by Hitachi-GE Nuclear Energy, aimed at ensuring a stable long-term power supply, reducing initial investment risk, and reducing the toxicity of radioactive waste. In the future, Hitachi-GE Nuclear Energy plans to continue working towards carbon neutrality by refining these plant designs and enhancing safety, while also continuously considering the societal needs for nuclear power and lessons learned from the Fukushima Daiichi nuclear power plant accident.

REFERENCES

- 1)

- Japan Atomic Industrial Forum, “Six More Countries Endorse the Declaration to Triple Nuclear Capacity,” (Nov. 2024) in Japanese.

- 2)

- Hitachi-GE Nuclear Energy, HI-ABWR Innovative Light-water Reactor in Japanese.

- 3)

- Hitachi, Ltd., “Development of Radioactive Substance Containment Equipment for Hitachi-GE’s HI-ABWR Innovative Light-water Reactor” (Mar. 2024) in Japanese.

- 4)

- Ontario Power Generation, OPG applies to Canadian Nuclear Safety Commission for License to Construct (Oct. 2022)

- 5)

- GE Vernova, SMRs, Deploy! GE Hitachi Signs Four-Party Agreement to Bring Small Module Reactors Online This Decade (Mar. 2023)

- 6)

- J. E. Donoghue et al., “Preapplication Safety Evaluation Report for the Power Reactor Innovative Small Module (PRISM) Liquid-Metal Reactor Final Report”, U. S. Nuclear Regulatory Commission, NUREG-1368 (Feb. 1994)