Service Development and Deployment of Solution for EV Charging and Delivery to Achieve Carbon Neutrality

Highlight

The promotion of green logistics over recent years has created demand for the electrification of trucks. Unfortunately, wider adoption has been impeded both by the limited scope for using EV trucks due to their short range and the higher electricity costs incurred when EV truck charging exceeds contracted limits on electricity supply. As a result, while there have been an increasing number of trials into the use of EV trucks for last-mile delivery, instances of full-scale adoption where EVs are used for the entire fleet operating out of a depot remain rare.

In an effort to create a sustainable society, Hitachi has developed an advanced logistics service provisionally named Hitachi Digital Solution for Logistics-EV that addresses these obstacles to EV adoption by the industry.

This article describes a charging scheduling function that interoperates with operational planning and presents example use cases.

Introduction

As automotive manufacturers in Japan as well as overseas have expanded their electric vehicle (EV) lineups over recent years, it is no longer unusual to see EVs on the streets. Meanwhile, progress has also been made on the electrification of trucks in the logistics industry, with Japanese automotive manufacturers having launched a number of small EV trucks during 2023. For EV trucks to become widely used, however, it will be necessary to overcome obstacles that include short range, high cost of adoption, and diminished delivery efficiency. As a result, the adoption of EVs in logistics has only progressed to the point where large freight companies and retailers are using small EV trucks for last-mile delivery on a trial basis, with few instances of depots switching all of their vehicles to EVs. Two of the main problems preventing the switch of entire fleets to EVs are the lack delivery scenarios for which EVs are suitable given their short range and the higher costs incurred when EV truck charging exceeds contracted limits on the supply of electric power.

This article describes work on a charging scheduling system that takes account of delivery plans for EV trucks and the outlook for the future. The goal is to overcome these challenges to encourage wider use of EV trucks and achieve sustainable logistics that cares for the environment.

Challenges in Using EV Trucks for Delivery

Challenges Relating to Management of Operations and Charging

The logistics industry is making greater use of EV trucks for last-mile delivery. This involves repeated trips in which the vehicle departs the depot, stops at a number of locations to pick up or drop of packages, and then returns to the depot. There is a gap of one to two hours between each trip.

The EV trucks in current use have a range of about 100 km. As they cannot travel as far as internal combustion engine (ICE) vehicles, this reduces the number of locations they are able to visit in a day by up to a few dozen. Minimizing the resulting need for additional vehicles is one of the requirements. On the other hand, this daily range can be extended by spending the time between trips charging at their home depot or by stopping to recharge at a public charging facility along their route.

Having many EV trucks charging at the same time increases the amount of electric power drawn from the grid. As the cost of electricity increases when peak power consumption exceeds the contracted limit, limiting peak demand is essential. This calls for a peak shifting capability that considers total demand for grid power, not just the electricity used for EV truck charging. Logistics depots are typically billed for electricity at a higher rate during the day than at night, meaning it is good practice to avoid any unnecessary charging during daytime business hours.

The use of ordinary EV chargers that always operate with a low output makes sense in terms of minimizing peak electricity demand. When charging at a depot during daytime business hours, however, the need is for rapid charging to recharge the vehicle sufficiently in the time available to avoid running out of battery on its next trip. If this is to be achieved, the number of trips to be made, the power consumption, the time available between trips, and the trend in depot power usage all need to be considered when deciding how long to spend charging and which charger to use. Likewise, when using a public charging facility, the charging time needs to be determined based on delivery deadlines and the need to avoid running out of battery charge.

Given these considerations, the efficient operation of EV trucks requires that charging be done at an appropriate time using a suitable charger that delivers the right amount of charge, while also keeping peak electricity demand to a minimum. On the other hand, as efficiency improvements that lead to greater operational complexity will impede practical deployment, they need to be combined with measures for reducing the depot’s workload.

Overview of Operational and Charging Management that Address Challenges for Logistics Operations

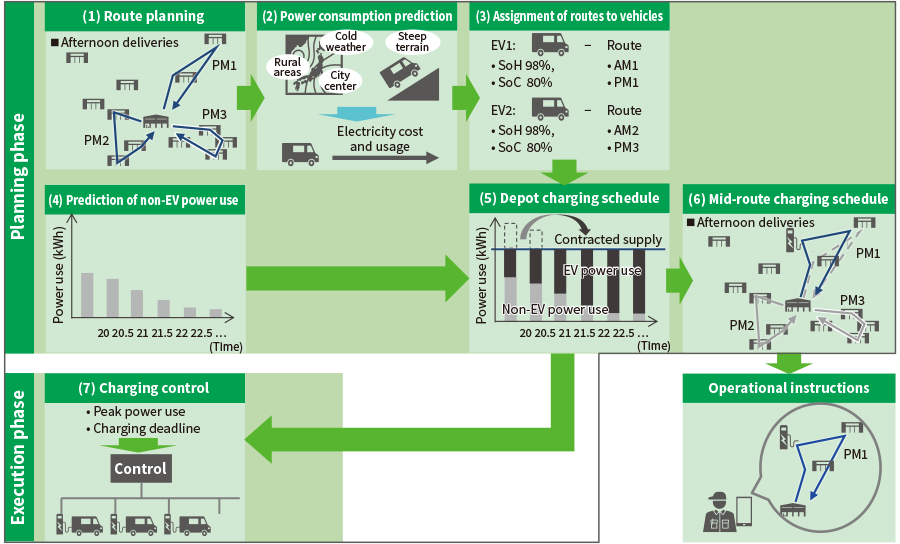

Figure 1—Overview of Operational and Charging Management for EV Delivery EV: electric vehicle, SOH: state of health, SOC: state of chargeOperational and charging management is made up of a planning phase for determining the optimal charging schedule and an execution phase for controlling charging in accordance with the schedule.

EV: electric vehicle, SOH: state of health, SOC: state of chargeOperational and charging management is made up of a planning phase for determining the optimal charging schedule and an execution phase for controlling charging in accordance with the schedule.

Figure 1 shows an overview of how Hitachi believes the delivery operations and charging of EV trucks can be managed in a way that resolves the challenges described above. This operational and charging management is divided into two stages: a planning phase for determining the optimal charging schedule and an execution phase that enables the vehicles to charge in accordance with this schedule.

The planning phase involves: (1) planning or predicting routes, (2) estimating the power consumption for each route, and (3) allocating EV trucks to routes. The next step is: (5) plan the charging schedule for each EV truck (mid-route or on return to the depot) so as to avoid the truck running out of battery charge before returning. Prior to this, step (4) involves predicting electricity usage at the depot for loads other than EV truck charging and using peak shifting to manage the overall supply of electric power from the grid. In cases where long-distance trips are unavoidable or the available charging facilities at the depot are inadequate, step (6) is to plan the route in a way that includes stopping at a public charging facility to avoid running out of battery charge.

The execution phase is comprised of: (7) automatically charging the EV trucks connected to chargers in accordance with the charging schedule. This involves prioritizing charging so that each EV truck can charge within the allocated time without exceeding the allotted peak electricity demand.

To operate EV trucks in this way, Hitachi has developed a service provisionally named the Hitachi Digital Solution for Logistics-EV (HDSL-EV) that offers a one-stop solution for supporting EV truck charging and delivery planning and is one of the functions in its Hitachi Digital Solution for Logistics suite of services for advanced logistics. HDSL-EV is divided into a charging scheduling function for use in the planning phase and a charging control function for use in the execution phase. The following section describes the charging scheduling function.

Delivery and Charging Scheduling Functions for HDSL-EV

This section describes the function for assigning routes to EVs and scheduling their charging and the function for scheduling mid-route charging, including explaining how they are used. These form part of the charging scheduling function used in the planning phase of Hitachi’s HDSL-EV delivery solution.

Functions for Assigning Routes to EVs and Scheduling Charging

The first of these functions assigns an EV truck to each route. When using ICE vehicles, long-distance routes and routes with a large volume of freight are assigned to large vehicles. In the case of EV trucks, however, in addition to vehicle type, the state of health (SOH) and state of charge (SOC) of the battery are also determining factors in the vehicle range (SOH indicates the condition of the battery and SOC indicates its remaining charge). For example, while an EV truck with a fully charged battery that has a 100% SOH may be able to complete a route on a single charge, a similar vehicle with an 80% SOH may need to recharge during its trip to avoid running out of battery power. Similarly, assigning vehicles with a high SOC to long-distance routes increases the likelihood that they will be able to complete the route without needing to recharge along the way. Accordingly, by taking account of SOH and SOC as well as vehicle type when assigning routes, HDSL-EV can reduce the amount of charging during daytime hours when the electricity consumption of the logistics depot is high. Furthermore, if a long-distance route or one that requires daytime charging is assigned to the same EV truck every day, its battery degradation will be greater than that of other EV trucks. To address this, Hitachi also developed a function that prevents excessive battery degradation by balancing the frequency of use and distance traveled evenly across the EV trucks. By providing functions like these, the solution is able to assign trucks in a way that avoids excessive battery degradation and keeps daytime charging to a minimum to help with peak shifting, and does so without requiring major changes to existing operating practices.

The charging scheduling function, meanwhile, schedules use of the different types of vehicles and chargers in a way that prevents the EV trucks from running out of battery and shifts peak demand for grid power. It can also minimize increases in electricity costs by switching between modes for respectively maximizing or minimizing charging based on the different electricity rates that apply at different times of the day. Functions are also provided for reducing the operational workload. When charging vehicles during the daytime, the solution offers a choice between improving charging efficiency or reducing driver workload. In the former case, EV trucks are moved as soon as they complete charging to free up limited charger availability, whereas the latter option leaves the EV trucks where they are after charging.

The function for charging scheduling includes the ability to specify where EV trucks are parked. Parking can be assigned in such a way that vehicles park in the same slot every day or driver workloads can be reduced by dispatching parallel-parked vehicles in order from the front of the line. In this way, the charging scheduling function of HDSL-EV can reduce workloads while also improving efficiency in ways that include reducing electricity costs, shifting demand peaks, and avoiding having vehicles run out of battery charge.

Scheduling of Mid-route Charging

The function for scheduling of mid-route charging is required to handle situations when it is not possible to charge at the depot due to a lack of facilities or available power from the grid, or long routes that a vehicle would not be able to complete on a single charge even if it leaves the depot with a full battery(1). The function minimizes the resulting loss of efficiency by obtaining information on the availability of local charging facilities from their energy management systems and optimizing the delivery route to include a stop at such a facility. The function also reduces waiting times and additional travel distance by adjusting the EV truck routes as well as when and where they charge to spread their use of charging facilities, thereby avoiding situations where a number of EV trucks need to charge at the same charger at the same time.

How Use of Delivery and Charging Scheduling Supports EV Truck Operations

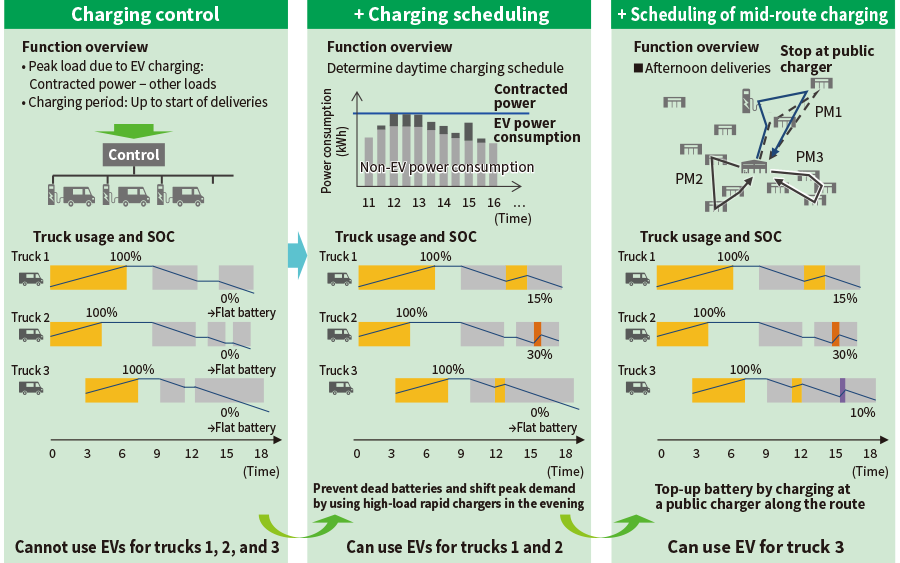

Figure 2—How Use of Delivery and Charging Scheduling Supports EV Truck Operations Use of daytime charging and mid-route charging increases the number of vehicles able to complete routes without running out of battery charge and helps switch the entire fleet to EVs.

Use of daytime charging and mid-route charging increases the number of vehicles able to complete routes without running out of battery charge and helps switch the entire fleet to EVs.

HDSL-EV supports the introduction of EV trucks by formulating schedules that help customers concerned about decarbonization to reduce their workloads and improve the operational efficiency of the trucks. Figure 2 shows an overview of how the function works.

The simplest operating practice would be to use the charging control function to perform ordinary charging in a way that stays within the contracted level of electricity supply during the time between the end of deliveries and their recommencement on the following day. The problem with this is that it will leave the EV trucks unable to operate on some routes due to a lack of charging facilities or inadequate vehicle range. In such cases, vehicle range can be extended by charging at the depot between deliveries. Trucks 1 and 2 in Figure 2 show an example of this. The risk, however, is that peak power may be exceeded if this results in a large number of trucks charging at the same time or having to use rapid charging. On the other hand, there is also a risk of being unable to charge the trucks sufficiently if the control regime requires lowering the peak power limit. In response, the charging scheduling function can help increase the ratio of EVs by performing peak shifting and by avoiding vehicles running out of battery charge. The ratio of EVs can also be increased by using the function that schedules mid-route charging to top-up the battery on routes that would otherwise be too long for an EV, as in the example of truck 3 in Figure 2.

Conclusions

Through the sophisticated integration of delivery and charging scheduling to overcome the business challenges posed by the switch to EVs, HDSL-EV is helping to create a carbon-neutral world with increased EV penetration. The goal for the future is to integrate with energy management systems (EMSs) so that photovoltaic power generation, energy storage, and EV batteries can be operated as if they were a single energy storage system, with control of charging and discharging combined with charging schedules that spread the energy load, ultimately going on to balance the energy load across all areas of society.

Hitachi also intends to develop total seamless solutions that make the entire supply chain greener and more efficient by seamlessly bridging the “kiwa” (gaps) between different activities, especially in logistics.