Laboratory Automation Platform Realized through One Hitachi

Highlight

While materials development has in the past been undertaken through a process of trial and error based on researchers’ intuition and experience, the field now makes routine use of materials informatics, leveraging data and digital technology for more sophisticated and rapid development. It is against this background that Hitachi has supplied numerous customers with Materials Informatics / AI for Materials Development that offer end-to-end support for the collection, management, and use of data for this purpose. Now, Hitachi is developing its Laboratory Automation Platform as one of the next major features to be added to its Materials Informatics / AI for Materials Development. The platform enables faster and more sophisticated materials development by automating measurement and analysis using a combination of data analysis and automated experimentation technologies.

This article presents an overview of Materials Informatics / AI for Materials Development and the Laboratory Automation Platform.

1. Introduction

In the past, new materials were developed through a process of trial and error that drew on the intuition and experience of the researchers. This involved considerable time and effort, in some cases taking several months of work to conduct just one of the experiments needed to develop a material. Against this background, the use of materials informatics (MI) for more advanced materials development and shorter development lead time has become routine, accompanied by a fundamental transformation of the materials development process brought about by materials-related data and digital technologies.

To promote wider and more sophisticated use of MI, Hitachi has since 2017 been supplying Materials Informatics / AI for Materials Development that offer end-to-end support for the collection, aggregation, management, and use of data for developing materials(1). These solutions have demonstrated their value for a wide range of customers engaged in fields such as organic and inorganic materials; ferrous and non-ferrous metals; pharmaceuticals; and lifestyle, food, and consumer products. Hitachi has also been developing its Laboratory Automation Platform (LAP) as one of the next major features to be added to its Materials Informatics / AI for Materials Development. The platform combines data analysis and automated experimentation technologies to automate measurement and analysis, transforming materials development into a cyber-physical system (CPS). By automating measurement and analysis, the platform enables faster and more sophisticated materials development. This article presents an overview of Materials Informatics / AI for Materials Development and the LAP.

2 Materials Informatics / AI for Materials Development and LAP

2.1 Materials Informatics / AI for Materials Development

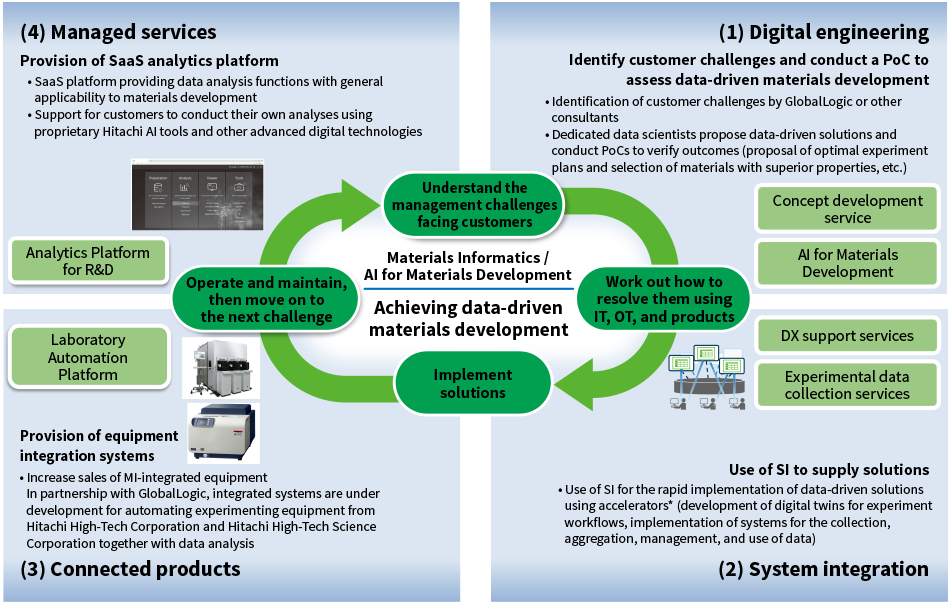

Materials Informatics / AI for Materials Development provide end-to-end support for the collection, aggregation, management, and use of data for developing materials. For this solution, the business design is based on the Lumada growth model(2). This is a circular business model that delivers ongoing value to customers by working through a four-quadrant cycle of: (1) Digital engineering, (2) System integration, (3) Connected products, and (4) Managed services. The following presents an overview of the solution based on the Lumada growth model (see Figure 1).

(1) Digital engineering

Hitachi offers a concept development service that organizes and understands the challenges customers face and formulates solutions along with a vision for the desired outcomes. Additionally, it offers an AI for Materials Development that undertakes a proof of concept (PoC) project utilizing data to assess the effectiveness of materials development practices. In the concept development service, dedicated consultants use consultation, discussion, workshops, and other such practices to engage with the customer and to identify and understand the challenges they face. By doing so, they work alongside the customer to determine what they need to be aiming for to achieve digital transformation (DX). They then draw on know-how acquired from extensive experience both inside and outside Hitachi, as well as solutions available from the Hitachi Group and further afield to propose solutions and actions that to be taken to achieve the desired outcome.

The AI for Materials Development also evaluates and investigates commercial use of data from internal and external sources and the associated analysis results, and assesses the effectiveness of data-driven materials development using data, artificial intelligence (AI), and digital technologies. Among the many examples are the use of analysis of data from past experiments to predict experimental conditions for achieving desired material properties, image processing to analyze how a material will perform based on images acquired using an electron microscope, and the extraction and analysis of information for new materials development from literature such as patents, papers, or in-house reports. PoC projects, meanwhile, support the adoption of MI by the customer by having data scientists with experience of various different types of data analysis assess the effectiveness of data-driven materials development in consultation with the customer.

(2) System integration

Hitachi supplies a DX support services that uses system integration to build solutions for the collection, aggregation, management, and utilization of the data that was identified, assessed, or proposed in the above digital engineering quadrant. The service achieves rapid system implementation though the use of “accelerators,” a pre-configured technology suitable for the rapid and repeated delivery of solutions. Experimental data collection services are also available, providing practices for the collection, aggregation, and management of the data required for advanced MI. These services allow customers to start small and then expand incrementally. This provides flexibility in deployment. It is possible, for example, to get services up and running in a single department to begin with, and then only extending them to other departments or company-wide once this has been successfully accomplished.

(3) Connected products

Hitachi is developing and supplying LAP for the automation of measurement and experimentation process by combining measurement and testing systems from Hitachi High-Tech Corporation with data analysis techniques from Hitachi, Ltd. Further details are provided in section 2.2 below.

(4) Managed services

Hitachi supplies an Analytics Platform for R&D in the form of a managed service. This platform distils the knowledge acquired from experience of numerous past PoC projects involving data analysis and other technologies and comes equipped with a suite of analytical algorithms with general applicability in the field of materials science. Customers can use the platform to conduct a wide variety of materials data analyses. It is accessed via a web browser and requires only a graphical user interface (GUI) for customers to upload the data for analysis and then click the buttons to specify the analysis conditions. The platform is made available as a software-as-a-service (SaaS).

The solution focuses on collaborative creation with customers to get new solutions up and running and then to extend their functions, working through the four quadrants to do so. As a result, the solution has come to be highly regarded both inside and outside Hitachi, delivering innovative solutions that resolve customers’ genuine challenges. Joint news releases have also been put out in partnership with a number of customers(3). The solution’s business model has likewise received recognition, winning the grand prize for 2022 at Hitachi’s in-house Lumada Business Awards.

Figure 1—Overview of Materials Informatics / AI for Materials Development Based on Lumada Growth Cycle OT: operational technology, PoC: proof of concept, SI: system integration, SaaS: software as a service, AI: artificial intelligence, MI: materials informatics

OT: operational technology, PoC: proof of concept, SI: system integration, SaaS: software as a service, AI: artificial intelligence, MI: materials informatics

* Pre-configured technology suites for the rapid and repeated delivery of solutionsHitachi supplies solutions that offer end-to-end support for the collection, aggregation, management, and utilization of data. This delivers ongoing value to customers by working through the businesses for each quadrant and then repeating the process.

2.2 Laboratory Automation Platform

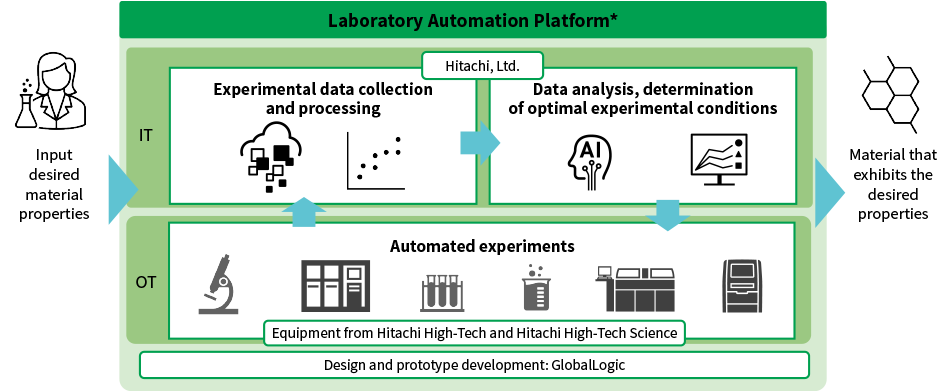

Hitachi is developing LAP as the next major function for Materials Informatics / AI for Materials Development. LAP automates measurement and analysis in materials development by transforming it into a CPS (see Figure 2). The following gives an outline of how LAP will work. The first step is for the user to enter the material properties they desire into the LAP system. In response, the AI utilizes existing experimental data to determine the conditions for subsequent experiments and then outputs these. The machine performs testing and measurement automatically based on these experimental conditions, with the experiment result being automatically uploaded to the cloud. Utilizing this new experimental data, the AI outputs another set of experimental conditions for further automatic experimentation. Repeatedly working through this process will result in a material that exhibits the properties desired by the user. In this way, the platform enables efficient and rapid materials development.

Implementing LAP demands a deep knowledge of materials development, materials data analysis capabilities, expertise in operational technology (OT) fields such as the engineering of measurement and testing systems, and the engineering and integration capabilities for designing and building advanced systems that enable the organic interoperation of other systems including analysis, equipment, and data collection functions. This is why the development of LAP has been undertaken as a partnership between Hitachi, Ltd., Hitachi High-Tech, and GlobalLogic, with Hitachi, Ltd. bringing extensive business experience and knowledge of working with materials manufacturers along with materials data analysis techniques and robust system integration capabilities. Similarly, Hitachi High-Tech brings high-level skills in the development of materials measurement and analysis systems that enjoy a large customer base while GlobalLogic has advanced system design capabilities together with “chip-to-cloud” engineering skills. Work on LAP started in earnest in 2022 and a minimum viable product (MVP) was completed in March 2024. Further functional enhancements are planned.

Figure 2—Overview of Laboratory Automation Platform * This solution is currently under development.The goal is to automate measurement and analysis in materials development by combining knowledge of measurement and testing systems and other OT with data analysis techniques and other IT.

* This solution is currently under development.The goal is to automate measurement and analysis in materials development by combining knowledge of measurement and testing systems and other OT with data analysis techniques and other IT.

2.3 Solution Manifesting One Hitachi and Hitachi Founding Spirit

The materials development solution and LAP won the grand prize for Japan, South Korea, and Oceania at Hitachi Group’s internal Inspiration of the Year Global Award (IYGA) for 2023. IYGA is a program that seeks to promote awareness of the Hitachi Group Identity, put it into practice, and foster the One Hitachi mindset. It recognizes the activities of group companies or divisions that exemplify the Hitachi Founding Spirit of Harmony, Sincerity, and Pioneering Spirit and helps to enhance the value of the Hitachi brand. The prize was awarded in recognition of how solution development and collaborative creation with customers were undertaken as One Hitachi, the pioneering spirit expressed in the goal of creating a world-first fully automatic LAP, and its future potential for global deployment. The following sections explain how Harmony, Sincerity, and Pioneering Spirit were manifested in the development of the solution.

(1) Harmony

As explained above, LAP was the result of Hitachi, Ltd., Hitachi High-Tech, and GlobalLogic working together as One Hitachi. It is a truly harmonious system, created through a fusion of each company’s strengths. Even within Hitachi, Ltd., participation in the development extended across a very wide range of organizations, including the Research & Development Group, GL Japan Business Operation, and other development and support divisions as well as the Government & Public Corporation Information Systems Division that acts as the product owner.

The project also faced difficulties in mutual understanding, with numerous obstacles in the form of differences in language, IT, OT, and roles as well as in expectations and development culture. In the case of IT and OT in particular, there were significant variations in solution development thinking and practices, language, and sense of urgency. Nevertheless, mutual understanding was deepened and these obstacles were overcome by taking a straight-forward approach to working through the activities of consulting with one another until agreement was obtained and a common vision was reached.

(2) Sincerity

The project was undertaken through collaborative creation with customers. The vision and functions of LAP were determined based on the views of a number of customers who were potential users of the platform. While the image of the system failed to take shape early on, with numerous instances of critical feedback where users complained that the proposed system was impractical, by sharing the vision it had for the platform and working in good faith through a repeated process of enthusiastic consultation and dialogue, Hitachi was able to transform these negative views into positive ones. Through activities like these, the customers, too, came to recognize the value of LAP more and more, to the extent that the MVP will be released to some of these customers.

(3) Pioneering Spirit

Looking internationally, a fully functioning LAP has not yet been realized. This is in large part due to technical shortcomings, including in the automation of measurement and testing systems and system-wide operational practices, making it difficult to implement all of the functions at once. By considering customer value and which functions are ready to be implemented, Hitachi clarified the overall architecture, which functions to develop at this point in time, and the development steps. It is fair to say that this task involved an exploration of the unknown. Both the system and its development were further enhanced by taking full advantage of the agile development and design thinking at which GlobalLogic excels.

3. Conclusions

This article has described a materials development solution and an LAP that were developed under the One Hitachi concept, embodying Hitachi’s Founding Spirit. In the future, Hitachi intends to deploy the technologies it has accumulated from past work and to expand their use beyond the materials sector to other manufacturing industries, including food, consumer goods, and biotechnology. Hitachi Group will also utilize its global touch points and actively promote the expansion of their use outside Japan, including to North America, Europe, and the Association of Southeast Asian Nations (ASEAN) region. As materials underpin all products, changing them can lead to changes in industry. As it seeks to energize entire industries, Hitachi will continue to enhance its solutions with the goal of using materials to transform the world.